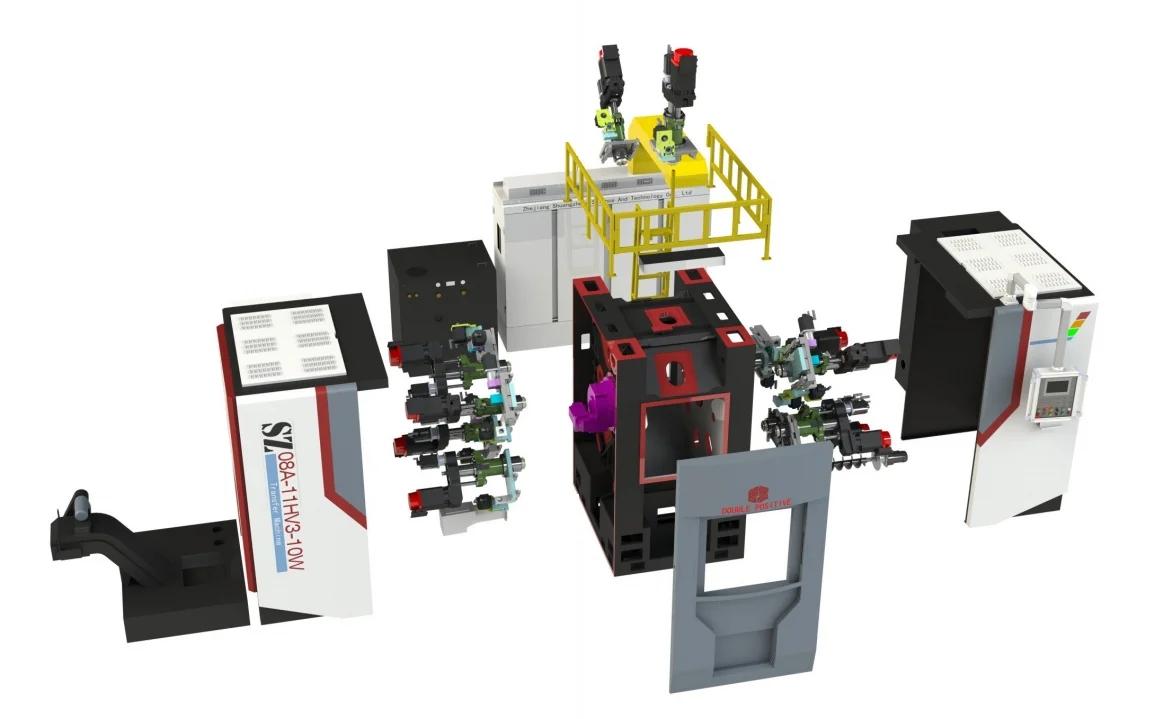

Fully Automatic CNC Machine is a commonly used machine tool equipment, widely used in the metal processing industry. In order to ensure the normal operation and safety of the machine tool, the preparation work before the test run is very important. This article will introduce some of the preparatory work before the test run of a Fully Automatic CNC Machine to help you run the test smoothly and ensure the performance and stability of the machine.

First, check the appearance and connection of the machine

1. Appearance inspection: Carefully check the appearance of the Fully Automatic CNC Machine to ensure that there is no obvious damage or deformation. Pay special attention to whether the key parts of the bed, guide rail, screw and so on are intact.

2. Connection check: Check the various connection parts of the machine tool, including the power line, air supply pipe, coolant pipe, etc. Make sure the connection is strong and reliable, and make the necessary tightening and adjustment.

Second, lubrication and cooling system preparation

1. Lubrication system: Check whether the oil of the lubrication system is sufficient, and ensure that the lubricating oil pump and oil circuit are smooth. If necessary, replace the lubricant and exhaust the system.

2. Cooling system: Check whether the coolant in the cooling system is sufficient, and clean the coolant filter. Coolant replacement and system flushing if necessary.

Fully Automatic CNC Machine debugging

Third, CNC system and program preparation

1. Check the CNC system: check whether the power supply and connection line of the CNC system are normal. Ensure that the display, control panel and operation buttons of the CNC system work properly.

2. Program preparation: Upload the pre-written machining program to the numerical control system, and verify and debug the program. Ensure the correctness and reliability of the program.

Iv. Safety measures and operating procedures

1. Safety measures: Ensure that the safety facilities around the machine tool are perfect, such as protective cover, emergency stop button, etc. Remind operators to follow the relevant safety operation procedures and wear personal protective equipment.

2. Operating procedures: Provide clear operating procedures and instructions to the operator, including the start, stop, emergency shutdown and other operating steps of the machine tool. Ensure that operators are familiar with and understand operating procedures.

The preparation work before the test includes checking the appearance and connection of the Machine tool, preparation of the lubrication and cooling system, preparation of the CNC system and procedures, and confirmation of safety measures and operating procedures.

Through careful inspection and preparation, ensure that all parts of the machine are working properly, the lubrication and cooling systems are operating properly, the numerical control system and procedures are correct, and the necessary safety measures and operation instructions are provided. Please carefully perform the above preparatory work before the test run to ensure the smooth operation and safe operation of the Fully Automatic CNC Machine.

Fully Automatic CNC Machine https://www.zjshuangzheng.com/Fully-Automatic-CNC-Machine-Category